If you're responsible for inspecting confined spaces, you know the risks. Traditional methods mean sending workers into potentially hazardous environments, dealing with poor visibility, and investing heavily in scaffolding and safety equipment. But what if there was another way?

Using a confined space drone – a game-changing tool designed to navigate even the tightest spaces – you can deliver high-quality visual data without putting workers at risk. Even in low-visibility conditions, the drone captures detailed footage to help you make informed decisions while reducing expenses and minimizing downtime.

The Problem with Confined Space Inspections

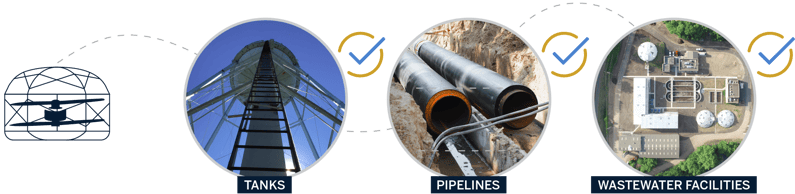

Inspecting confined spaces like tanks, pipelines, and wastewater facilities comes with its fair share of challenges. Limited access, hazardous conditions, and costly safety requirements make these inspections complex and time-consuming. Traditional methods often require workers to physically enter these environments, exposing them to toxic gases, poor visibility, and structural instability. On top of that, there’s the added expense of extensive safety protocols and equipment requirements – making the process not only risky but also financially burdensome.

That’s where confined space drones come in.

Introducing the Flybotix ASIO X – Conqueror of Confined Spaces

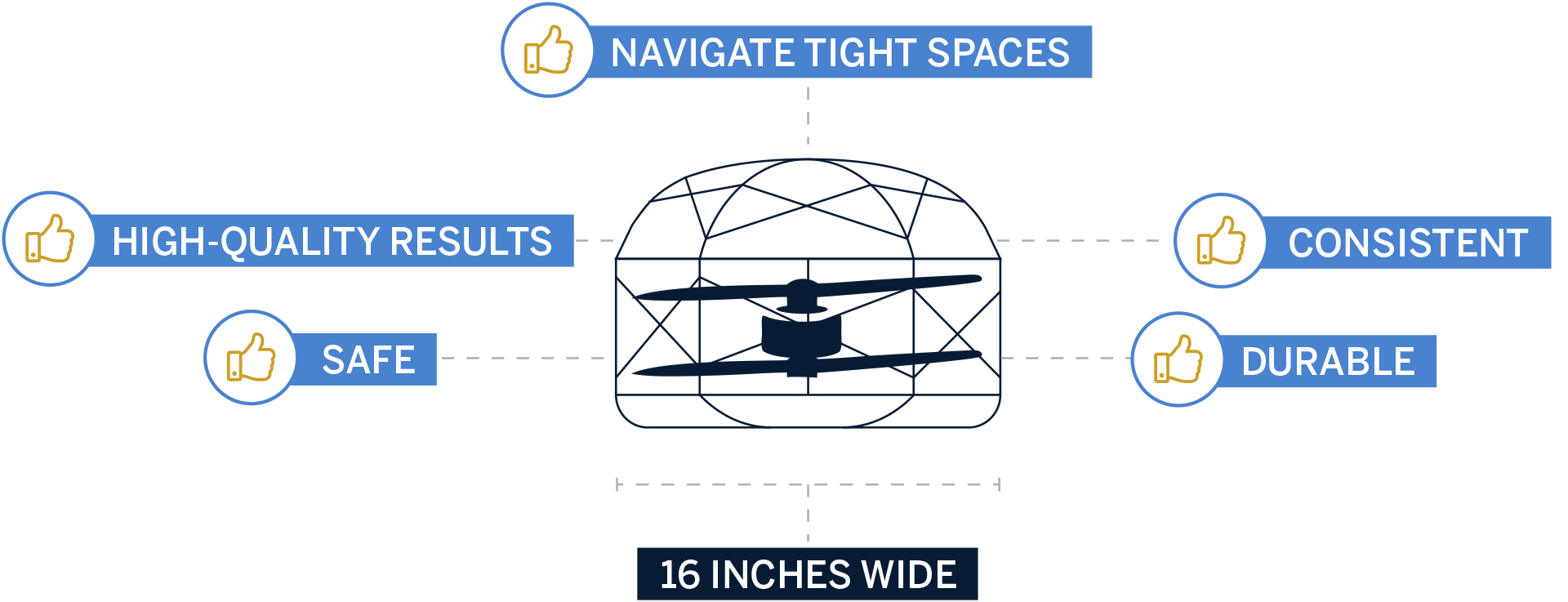

Measuring just 16 inches wide, the ASIO X can navigate through incredibly tight openings without compromising performance. Its durable build allows it to withstand demanding conditions, ensuring consistent, high-quality results in the toughest environments.

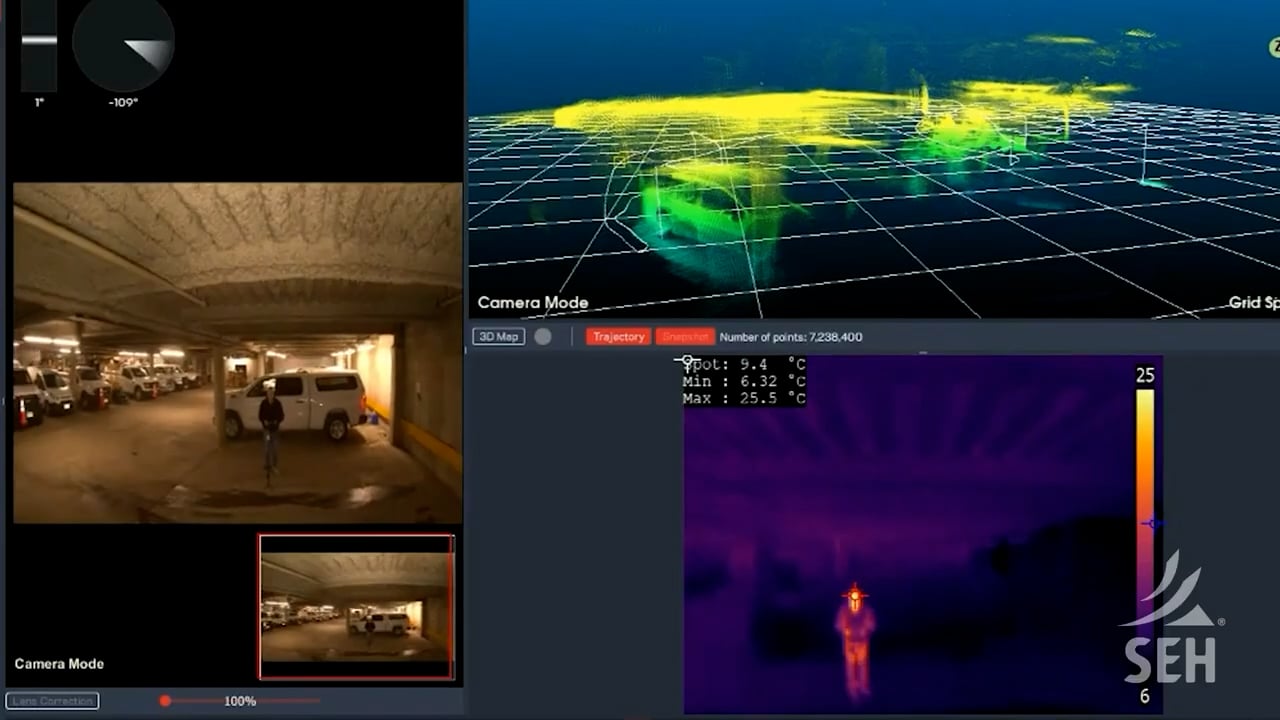

Equipped with advanced technology, this drone delivers high-quality inspections with precision and efficiency. A high-resolution camera paired with 40,000-lumen lighting provides crystal-clear visuals, even in complete darkness. The drone’s four gas sensors continuously monitor air quality, adding an extra layer of safety to every inspection. For accurate navigation and detailed mapping, it features radar, LiDAR, and infrared capabilities, allowing it to detect obstacles and capture structural data. Unlike traditional drones that rely on GPS, the ASIO X uses Inertial Measurement Units (IMUs), enabling it to operate seamlessly in GPS-denied environments such as tunnels, tanks, and underground infrastructure.

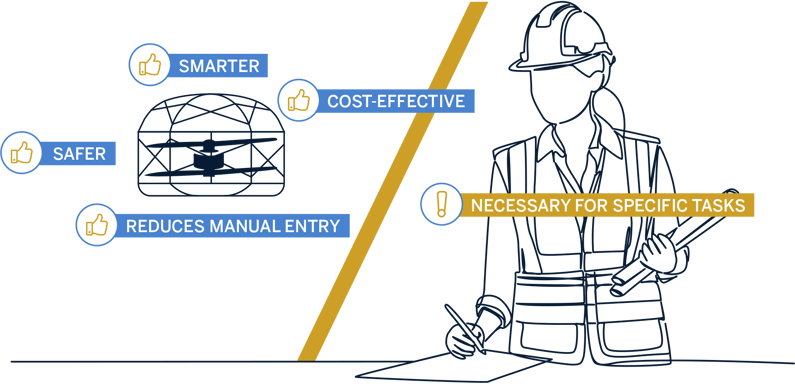

As a recent addition to SEH’s diverse drone fleet, we're excited about how the ASIO X enhances the ability to serve industries that rely on precision and safety in hard-to-reach spaces. This new technology opens the door to more versatile inspection capabilities across a range of sectors, providing real-time, actionable data that helps identify potential risks for improved decision-making. While manual entry may still be necessary for some specific tasks, this drone technology reduces the frequency of these entries, making inspections smarter, safer, and more cost-effective.

Community Use Cases and Benefits

Seeing this technology in action is where its true value becomes clear. Here’s how it’s transforming inspections and driving value for communities:

Water and Wastewater Infrastructure

Municipalities and utilities use drones to inspect underground sewer systems, water storage tanks, and treatment plant infrastructure. With the ability to collect clear, detailed imagery, these drones help teams spot structural issues, corrosion, or blockages. By providing real-time data, they support proactive maintenance and reduce the need for system shutdowns or manual inspections.

Industrial and Manufacturing Facilities

Manufacturers rely on drones to inspect boilers, storage silos, and ventilation shafts. By eliminating the need for scaffolding or manual entry, companies reduce downtime and safety risks while ensuring regulatory compliance. The ability to conduct frequent, non-invasive inspections helps prevent major equipment failures and unplanned interruptions.

Energy and Utilities

Power plants, refineries, and substations have numerous confined spaces requiring routine inspections, including pipelines, turbines, and cooling towers. Drones equipped with thermal imaging and gas detection sensors provide real-time data on equipment conditions, allowing for predictive maintenance and early detection of leaks or structural weaknesses.

Tunnels and Enclosed Spaces

By enabling faster, non-invasive inspections of tunnels and culverts, drones help communities maintain safe and efficient transportation networks. Traditional methods often require lane closures and heavy equipment, leading to traffic disruptions and placing added strain on public resources. Drones streamline this process, allowing engineers to quickly assess structural integrity while keeping roads open. This means fewer delays for commuters, improved infrastructure longevity, and better allocation of public resources for critical maintenance projects.

Ready to Upgrade Your Inspections?

Confined space inspections don’t have to be high-risk, time-consuming, or costly. With drone technology, you gain a safer, more efficient way to collect the data you need – without putting workers in harm’s way. From water infrastructure to industrial facilities and energy plants, drones are redefining inspections by reducing downtime, improving safety, and delivering precise, actionable insights.

Ready to rethink your approach? Contact us to explore how drone technology can enhance your inspection process.

Our confined space drone, or as we like to call her – Connie – is always up for a challenge! Whether she’s navigating biogas spheres, squeezing through wastewater channels, or tackling plant inspections, Connie is redefining confined space exploration one flight at a time. Want to see where she’s headed next? Follow her adventures on our social channels and stay tuned for her latest missions!

Bailey Nelson is a Part 107 certified Drone Operations Specialist and Project Manager at SEH. With five years of experience in the drone industry and a background in aviation, she also holds a private pilot license. Additionally, she collaborates with SEH staff and external clients to develop drone-related solutions for engineering, planning, and natural resources challenges.

Dasan Hood Backman is a Commercial Pilot and Part 107 Drone Specialist at SEH. He has accrued thousands of hours in both manned and unmanned aircraft over the past decade. He enjoys being in the field, documenting various SEH projects.

.png?width=113&name=SEH_Logo_RGB%20(1).png)